At Green Bond, we specialize in manufacturing high-performance tile adhesives tailored for Indian conditions. Our advanced production lines ensure precision blending and consistent quality.

Our adhesives are available in multiple packaging options including 20kg & 40kg packets, and 50kg & 100kg buckets, designed to meet the diverse needs of residential, commercial, and industrial projects.

Our manufacturing facility is designed for efficiency, accuracy, and scale. We have integrated cutting-edge technology such as automated high-speed mixers, digital batch weighing systems, and fully automated packing lines to deliver consistent product quality every time.

From material feeding to final packaging, every process is monitored in real-time using our digital control systems, minimizing human error and maximizing output. We also follow a green production approach by reducing waste, recycling materials where possible, and ensuring proper ventilation, dust control, and worker safety across the plant. Our commitment to eco-friendly practices ensures sustainability alongside scalability.

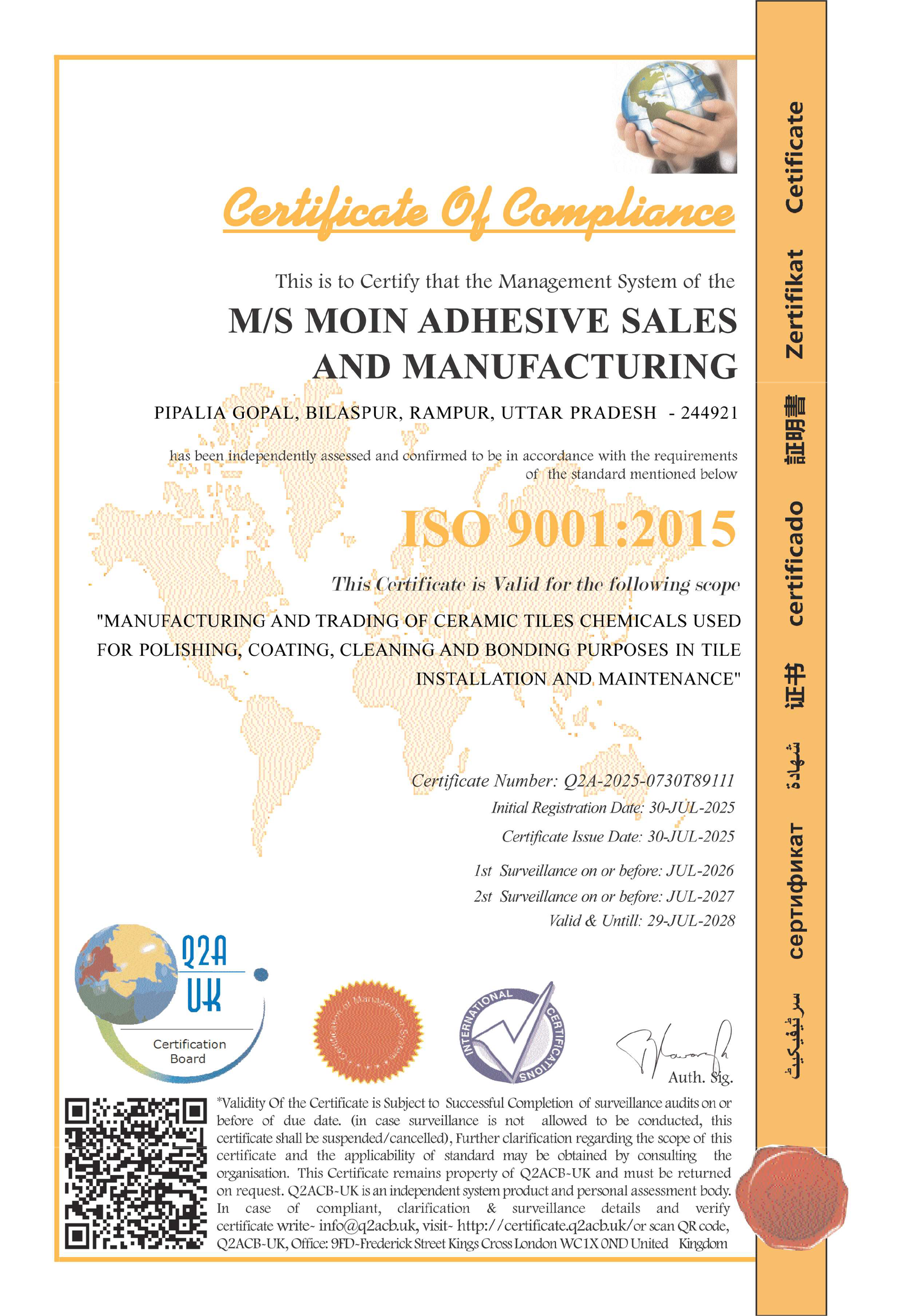

Our manufacturing unit is ISO 9001:2015 certified, ensuring global quality standards. Every batch undergoes strict quality control for bond strength, drying time, and durability.

Our commitment to quality and compliance ensures long-lasting performance of our adhesives across all applications.

Each production batch is assigned a unique batch number and is accompanied by detailed quality reports. This ensures full traceability — from raw material sourcing to final delivery — offering complete transparency to our customers and distributors.

We maintain a dedicated in-house laboratory with modern testing equipment where samples are tested for compressive strength, water retention, slip resistance, and open time to meet Indian and international tiling standards.

Our team undergoes regular training to stay updated with evolving quality standards and manufacturing best practices. This culture of continuous improvement ensures that every Green Bond product not only meets but often exceeds industry expectations.

Being ISO-certified is not just a badge; it reflects our consistent effort to improve internal processes, reduce errors, and build trust with clients across residential, commercial, and export markets. When you choose Green Bond, you're choosing a brand that values quality at every level.

From research and development to production and packaging, every step is meticulously handled under

one roof. This in-house manufacturing approach not only ensures faster delivery and competitive

pricing but also guarantees superior quality and consistency. That’s why Green Bond tile adhesives

are the preferred choice of builders, contractors, and retailers across India, known for their

long-lasting performance and unmatched durability.

We stand by our commitment to innovation, safety, and customer satisfaction. Choose Green Bond —

where every bag is a promise of quality.

© GreenBond | Developed by AppUncles